Advantage:

1. Inventional patent design heating channel with side-open stand, convenient for heating lamps replacement and machine maintenance;

2. Compact setting preform holders, no chain moving, performs stay in heating channel for longer time heating, saving power consumption.

3. Imported PLC automation control enable non-stop machine parameter adjustment.

4. Suitable for auto production of oil bottles, jars, and irregular neck containers.

5. World famous brand pneumatic components.

6. World famous brand electrical components.

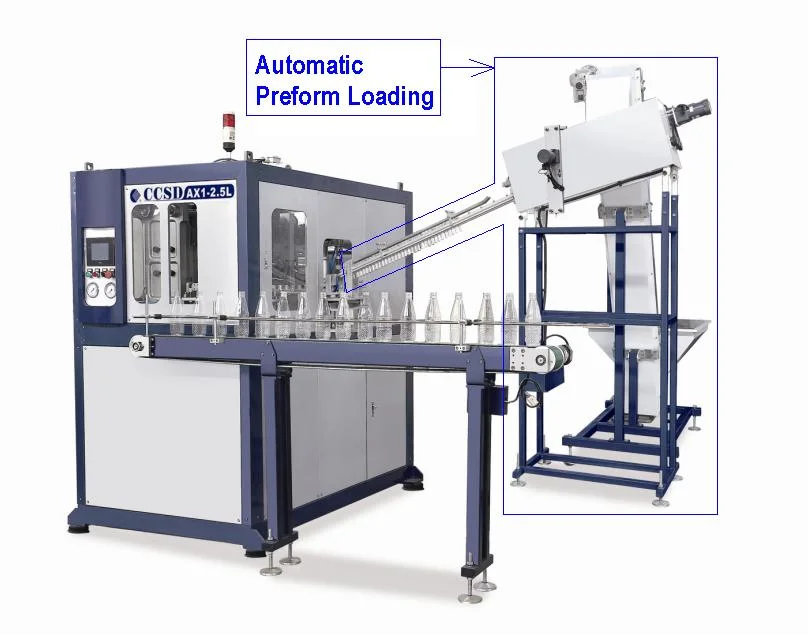

Model CSD-AX1-2.5L Blow Molding machine is with Automatic Preform Loading.

Model CSD-AX1-M-2.5L Blow Molding machine is with Manual Preform Loading.

The mainly different part had been showed in following picture.

1. Inventional patent design heating channel with side-open stand, convenient for heating lamps replacement and machine maintenance;

2. Compact setting preform holders, no chain moving, performs stay in heating channel for longer time heating, saving power consumption.

3. Imported PLC automation control enable non-stop machine parameter adjustment.

4. Suitable for auto production of oil bottles, jars, and irregular neck containers.

5. World famous brand pneumatic components.

6. World famous brand electrical components.

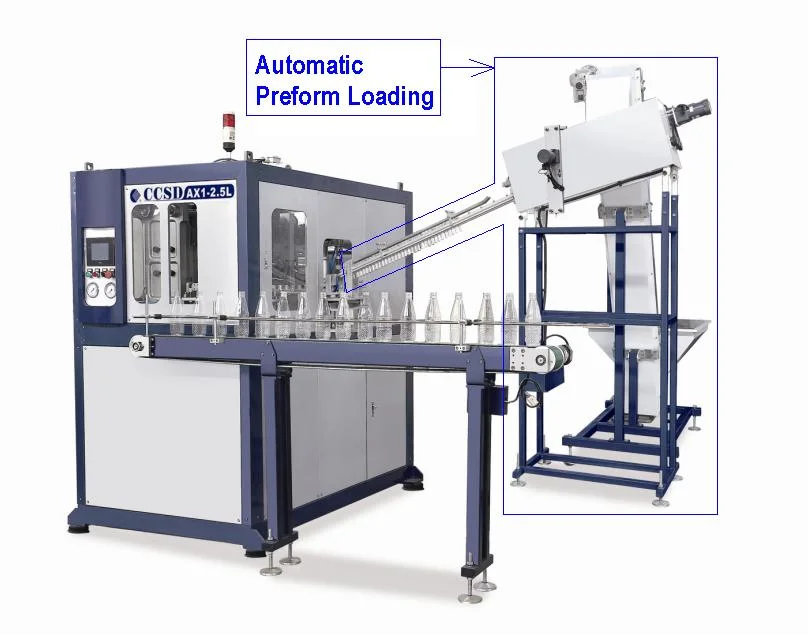

Model CSD-AX1-2.5L Blow Molding machine is with Automatic Preform Loading.

Model CSD-AX1-M-2.5L Blow Molding machine is with Manual Preform Loading.

The mainly different part had been showed in following picture.

| AX SERIES BLOW MOLDING MACHINE | ||||||

| Item | UNIT | CSD-AX1-2.5L | CSD-AX2-2L | CSD-AX3-1.5L | CSD-AX4-1.5L | |

| Cavity | 1 | 2 | 3 | 4 | ||

| Product volume | L | ≤ 2.5L | ≤ 2L | ≤ 1.5L | ≤ 1.5L | |

| Recommend Production Capacity | Pcs/h |

1100-1600Pcs/h Based on 500ml bottle, Preform Neck 28-30mm Weight: 17gram |

2100-2400Pcs/h Based on 500ml bottle, Preform Neck 28-30mm Weight: 17gram |

2900-3200Pcs/h Based on 500ml bottle, Preform Neck 28-30mm Weight: 17gram |

3900-4200Pcs/h Based on 500ml bottle, Preform Neck 28-30mm Weight: 17gram |

|

| Max.Diameter of Product | mm | φ 120 | φ 100 | φ 90 | φ 90 | |

| Neck Size of Product | mm | φ 15-φ 38 | φ 15-φ 38 | φ 15-φ 38 | φ 15-φ 38 | |

| Useful Area of Mould Plate | mm | 200× 350 | 300× 350 | 380× 350 | 480× 350 | |

| Mould Thickness | mm | 200 | 200 | 200 | 200 | |

| Mould Stroke | mm | 160 | 160 | 110 | 110 | |

| Clamping Force | Kn | 120 | 120 | 120 | 210 | |

| Stretching Stroke | mm | 450 | 430 | 430 | 430 | |

| Working Pressure | Mpa | 0.8-1.0 | 0.8-1.0 | 0.8-1.0 | 0.8-1.0 | |

| Blowing Air Pressure | Mpa | 2.6-3.0 | 2.6-3.0 | 2.6-3.0 | 2.6-3.0 | |

| Measurement of Main Blower | mm | 1820× 1100× 1900 | 2280× 1500× 1900 | 2650× 1780× 1900 | 2810× 2000× 1900 | |

| Power of Preheater | Kw | 32 | 36 | 70 | 72 | |

| A | 48 | 54 | 105 | 108 | ||

| Power of Main Blower | Kw | 3 | 3 | 5 | 5 | |

| Weight of Main Blower | T | 1.5 | 2 | 2.5 | 3 | |

| Measurement of Conveyer | mm | 2570× 2570× 2700 | 2570× 2570× 2700 | 2570× 2570× 2700 | 2890× 2570× 2700 | |

| Weight of Conveyer | T | 0.2 | 0.2 | 0.2 | 0.2 | |

| HIigh Pressure Air Compressor Unit | Power | Kw | 18.5 | 18.5 x 2 | 22 x 2 | 22 x 2 |

| Pressure | Mpa | 3.0 | 3.0 | 3.0 | 3.0 | |

| Discharging Capa. | m³ /min | 1.5 | 3 | 4 | 4 | |

| Low Pressure Air Compressor Unit | Power | Kw | ___ | 11 | 11 | 22 |

| Pressure | Mpa | ___ | 1.25 | 1.25 | 1.25 | |

| Discharging Capa. | m³ /min | ___ | 1.6 | 1.6 | 3.0 | |

| Air Tank | Capacity | M³ | ___ | 0.6 | 0.6 | 0.6 |

| Working Pressure | MPa | ___ | 3.0 | 3.0 | 3.0 | |

| Water Chiller | Cooling Capacity | Kcal/h | 11900 | 11900 | 11900 | 24090 |

| CompressorMotor | HP | 5 | 5 | 5 | 10 | |

|

Air Filter Oil Filter Odor Removal Filter |

Capacity | m³ /min | 2 | 3 | 4 | 4 |

| Working Pressure | MPa | 3.0 | 3.0 | 3.0 | 3.0 | |

| Item | UNIT | CSD-AX1-5L | CSD-AX1-M-5GAL | CSD-AX2-W-5L | CSD-AX2-M-10L | CSD-AX2-M-5L | |

| Cavity | 1 | 1 | 2 | 2 | 2 | ||

| Product volume | L | ≤ 5L | ≤ 5GAL | ≤ 5L | ≤ 10L | ≤5L | |

| Recommend Production Capacity | Pcs/h |

700-850Pcs/h Based on 5L bottle, Preform Neck 45mm Weight: 93gram |

220-240Pcs/h Based on 5L bottle, Preform Neck 55mm Weight: 750gram |

1400-1500Pcs/h Based on 5L bottle, Preform Neck 45mm Weight: 93-120gram |

1100-1200Pcs/h Based on 5L bottle, Preform Neck 45mm Weight: 93-120gram |

1400-1500Pcs/h Based on 5L bottle, Preform Neck 80mm Weight: 93gram |

|

| Max.Diameter of Product | mm | φ 170 | φ 270 | φ 180 | φ 200 | φ 170 | |

| Neck Size of Product | mm | φ 38-φ 45 | φ 45-φ 60 | φ 60-φ 120 | φ 45-φ 60 | φ 38-φ 45 | |

| Useful Area of Mould Plate | mm | 240× 400 | 400× 570 | 420× 320 | 600× 460 | 550× 400 | |

| Mould Thickness | mm | 240 | 400 | 250 | 300 | 240 | |

| Mould Stroke | mm | 220 | 330 | 200 | 240 | 220 | |

| Clamping Force | Kn | 240 | 300 | 300 | 300 | 240 | |

| Stretching Stroke | mm | 450 | 660 | 380 | 590 | 450 | |

| Working Pressure | Mpa | 0.8-1.0 | 0.8-1.0 | 0.8-1.0 | 0.8-1.0 | 0.8-1.0 | |

| Blowing Air Pressure | Mpa | 2.6-3.0 | 2.6-3.0 | 2.6-3.0 | 2.6-3.0 | 2.6-3.0 | |

| Measurement of Main Blower | mm | 2350× 1550× 1900 | 4200× 2000× 2300 | 3200× 2000× 1900 | 3200× 2000× 2200 | 3200× 2000× 2200 | |

| Power of Preheater | Kw | 48 | 117 | 84 | 60 | 60 | |

| A | 72 | 175 | 126 | 90 | 90 | ||

| Power of Main Blower | Kw | 3 | 5 | 5 | 5 | 5 | |

| Weight of Main Blower | T | 2 | 4.5 | 3.5 | 3.5 | 3.5 | |

| Measurement of Conveyer | mm | 2570× 2570× 2700 | ___ | ___ | ___ | ___ | |

| Weight of Conveyer | T | 0.2 | ___ | ___ | ___ | ___ | |

| HIigh Pressure Air Compressor Unit | Power | Kw | 22 x 2 | 22 x 4 | 22 x 3 | 22 x 4 | 22 x 4 |

| Pressure | Mpa | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | |

| Discharging Capa. | m³ /min | 4 | 6 | 6 | 10 | 8 | |

| Low Pressure Air Compressor Unit | Power | Kw | 11 | 22 | 22 | 30 | 22 |

| Pressure | Mpa | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | |

| Discharging Capa. | m³ /min | 1.6 | 3.0 | 3.0 | 4.0 | 3.0 | |

| Air Tank | Capacity | M³ | 0.6 | 2 x 2 | 0.6 x 2 | 2 | 2 |

| Working Pressure | MPa | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | |

| Water Chiller | Cooling Capacity | Kcal/h | 11900 | 11900 | 35200 | 35200 | 35200 |

| CompressorMotor | HP | 5 | 5 | 10 | 10 | 10 | |

|

Air Filter Oil Filter Odor Removal Filter |

Capacity | m³ /min | 1 | 6 | 6 | 10 | 8 |

| Working Pressure | MPa | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | |